Exploring the relationship between reverse logistics and sustainability performance: A literature review

Modern Supply Chain Research and Applications

ISSN : 2631-3871

Article publication date: 18 June 2019

Issue publication date: 3 September 2019

The implementation of reverse logistics (RL) as a strategic decision has gained significant attention amongst organisations due to its benefits to sustainable development. The purpose of this paper is to provide a comprehensive review of the literature to evaluate the performance of the RL process based on the three dimensions of sustainability including environmental, economic and social aspects.

Design/methodology/approach

Content analysis was adopted to collect and analyse the information.

The findings of this research show that most of the studies have focused on the performance evaluation of RL by considering the factors associated with economic and environmental performance. The social aspect of RL has been overlooked and requires investigation due to its contribution to positive social outcomes. In addition, no research has been conducted to assess the impact of each of the disposition options on the triple-bottom-line sustainability performance in one study.

Originality/value

Although RL can make a significant contribution to improving the sustainability performance of firms, little research has been undertaken on exploring the relationship between RL and sustainability performance. This paper provides practitioners, academics and researchers a broad and complete view of the relationship between RL and sustainability performance with suggestion for future research.

- Reverse logistics

- Sustainability

- Sustainability performance

- Environmental and social impact

- Triple-bottom-line sustainability

Banihashemi, T.A. , Fei, J. and Chen, P.S.-L. (2019), "Exploring the relationship between reverse logistics and sustainability performance: A literature review", Modern Supply Chain Research and Applications , Vol. 1 No. 1, pp. 2-27. https://doi.org/10.1108/MSCRA-03-2019-0009

Emerald Publishing Limited

Copyright © 2019, Taknaz Alsadat Banihashemi, Jiangang Fei and Peggy Shu-Ling Chen

Published in Modern Supply Chain Research and Applications. Published by Emerald Publishing Limited. This article is published under the Creative Commons Attribution (CC BY 4.0) licence. Anyone may reproduce, distribute, translate and create derivative works of this article (for both commercial and non-commercial purposes), subject to full attribution to the original publication and authors. The full terms of this licence may be seen at http://creativecommons.org/licences/by/4.0/legalcode

1. Introduction

Sustainability has become a strategic intent for almost all businesses in the twenty-first century because of its contribution to profitability and growth and even the survival of a business ( Corbett and Klassen, 2006 ; Kolk and Pinkse, 2008 ). Sustainability in the supply chain has gained attention in recent years due to community concerns about the environment and organisations’ adoption of “green” strategies and recognition of their social responsibility; the need to respond to legislation aimed to reduce environmental impacts; and the realities of challenging market and economic competition ( Agrawal et al. , 2016b ). Organisations can gain more profit and sustain their businesses over long term by adopting sustainability principles ( Székely and Knirsch, 2005 ). Thus, developing practices that increase sustainability are considered to be a critical goal for organisations due to their contribution to competitive advantage ( Hart, 2005 ; Pfeffer, 2010 ). Organisations need to evaluate and analyse the environmental and social performance of their business in addition to their economic performance ( Agrawal et al. , 2016b ).

Reverse logistics (RL) is a logistics function focusing on the backward flow of products from customers to suppliers ( Hazen, 2011 ). RL is a crucial component of green supply chain management (GSCM) as it can help to reduce the waste generated by handling and disposition of returned and used products through employing a range of disposition options ( Hervani et al. , 2005 ; Pokharel and Mutha, 2009 ). Product returns can occur for a number of reasons and at different places in the supply chain including manufacturing, distribution and customer-related returns ( Rogers and Tibben-Lembke, 1999 ; Flapper, 2003 ). Product disposition involves activities associated with making a decision about what to do with used or returned products and this process is a key part of RL ( Prahinski and Kocabasoglu, 2006 ). Reuse, repair, remanufacturing, recycling and disposal have been defined as the common disposition options of RL ( Thierry et al. , 1995 ; De Brito and Dekker, 2002 ; Pokharel and Mutha, 2009 ).

Well-managed RL programs can lead to sustainable development and create a competitive advantage through increased profits, cost reduction and improvement in customer satisfaction ( Rogers and Tibben-Lembke, 1999 ; Stock et al. , 2002 ). RL can produce both tangible and intangible benefits by recapturing value from used or returned products and extending the life of products, rather than purchasing more raw materials and wasting manpower and time. In addition, RL can play a key role in customer satisfaction and thus maintaining their loyalty by paying attention to fixing or replacing faulty products. Furthermore, RL can result in improvements in future products or new product designs by incorporating feedback from customers and understanding the reasons for product returns ( Aitken and Harrison, 2013 ).

Much of the research so far has focused on the economic and environmental benefits of RL. There is a lack of research investigating the relationship between RL and sustainability and evaluating how RL can improve sustainability performance by integrating the three pillars of sustainability performance. This study reviews literature related to RL and sustainability performance and evaluates the performance of the RL process through three dimensions of sustainability, that is, the environmental, economic and social aspects. The remainder of this paper is organised as follow: the following section reviews different definitions of RL and its processes, and examines the difference between RL and forward logistics. Next, the three aspects of sustainability performance and their indicators are examined. The research methodology is presented in the next section, followed by a discussion of the relationship between RL and sustainable development. Finally, the paper summarises the discussion and concludes by suggesting future research.

2. RL processes

Over recent years, research on RL has increased significantly and its definition has changed over time. Murphy and Poist (1988) provided the earliest definition of RL by referring to the reverse flow of goods. Later the term “environment” appeared in the definition of RL by Carter and Ellram (1998) and they considered RL to be an environmentally friendly approach. RL has been defined as “The term most often used to refer to the role of logistics in product returns, source reduction, recycling, materials substitution, reuse of materials, waste disposal, and refurbishing, repair and remanufacturing” ( Stock, 1998 , p. 20). This definition refers to different disposition options in the RL process. RL is also defined as “the process of planning, implementing, and controlling the efficient, cost-effective flow of raw materials, in-process inventory, finished goods and related information from the point of consumption to the point of origin for the purpose of recapturing value or proper disposal” ( Rogers and Tibben-Lembke, 1999 , p. 2). They created the most widely accepted definition of RL by introducing the purpose of RL.

Significant difference exists between RL and forward logistics in terms of process and purpose ( Tibben-Lembke and Rogers, 2002 ). RL deals with the activities associated with taking back products from customers for recapturing value through reprocessing or proper disposal, while forward logistics contains the activities that are necessary to get products to the customers. Most of the research on supply chain and logistics management has focused on forward logistics, while RL has been neglected ( Stock et al. , 2002 ; Bernon and Cullen, 2007 ).

RL and forward logistic processes are illustrated in Figure 1 . RL starts with the end users (consumers in Figure 1 ) from whom the used or returned products are collected, moved through product acquisition at which stage the products are inspected and sorted into various groups. The next step is to make an appropriate disposition decision including reuse, repair, remanufacturing or recycling for recapturing value or disposal. The key RL processes include product acquisition, collection, inspection/sorting and disposition ( Rogers and Tibben-Lembke, 1999 ; Fleischmann et al. , 2000 ; Guide and Wassenhove, 2003 ).

2.1 Product acquisition/gate keeping

The process of acquiring used products from the end users for further processing is known as product acquisition. This is an important consideration with respect to the success of RL because of uncertainty regarding time, quantity and quality of used products ( Agrawal et al. , 2015 ). Gate keeping is a set of decisions about whether products must be sent for further processing or given back to the consumer, and is usually implemented by retailers ( Agrawal et al. , 2015 ).

2.2 Collection

Collection is the process of collecting products after the acquisition and sending them to other facilities for inspection, sorting and disposition. Kumar and Putnam (2008) categorised collection methods into three groups: manufacturers directly collecting from customers, manufacturers collecting returned products via retailers and manufactures collecting products through third-party logistics. The selection of collection methods is dependent on cost structure and quantities ( Atasu et al. , 2013 ). The selection of collection centres and recovery facilities must be involved in designing RL if it is to operate efficiently ( Pochampally and Gupta, 2004 ).

2.3 Inspection and sorting

Products are inspected and sorted after collection. Product returns may be manufacturing, distribution or customer related ( Rogers and Tibben-Lembke, 1999 ; Guide and Wassenhove, 2003 ) and they may differ greatly in terms of quality and condition. Thus, it is necessary to inspect the products separately for sorting into different groups for disposition ( Agrawal et al. , 2015 ).

2.4 Disposition

Reuse requires only minor inspection, cleaning and maintenance ( Fleischmann et al. , 2000 ) without disassembly, reprocessing and reassembly activities ( Matsumoto, 2010 ). This process requires less work in comparison with other options ( Fleischmann et al. , 2000 ).

Repair denotes the process of repairing and servicing products and returning them to customers ( Fleischmann et al. , 2000 ).

Remanufacturing is related to material recovery from products with high value ( Blackburn et al. , 2004 ). The process of replacing obsolete or faulty parts with new or refurbished ones is incorporated under this term. In this process, the identity and functionality of the original product materials are maintained ( Eltayeb et al. , 2011 ). Remanufactured products are redistributed and sold into the potential market. Companies need to identify the proper markets for these products, choosing between selling them alongside new products, via discount stores, in secondary markets or donating them to charity ( Rogers and Tibben-Lembke, 1999 ).

Recycling is related to material recovery from products with low value ( Blackburn et al. , 2004 ) and involves processes to extract reusable materials from used products. The identity and functionality of the original product materials are lost ( Khor et al. , 2016 ). Recycling is chosen when the original product or component can be used for another product or subassembly ( Skinner et al. , 2008 ).

Disposal is the process of incinerating products or components or using them for landfill. Disposal is chosen when the products cannot be sold or reused and the other options of disposition are not effective ( Khor et al. , 2016 ).

3. Sustainability performance

Sustainability has become a strategic issue for firms ( Álvarez-Gil et al. , 2007 ; Lee and Lam, 2012 ). From a triple-bottom-line perspective, sustainability is considered to be the integration of environmental, economic and social objectives that provides a balance between the three aspects ( Elkington, 2001 ; Carter and Rogers, 2008 ; Gunasekaran and Spalanzani, 2012 ). Nowadays firms are understood to have responsibilities for the environment and society. As Hubbard (2009) stated, almost 75 per cent of large international organisations are under pressure to consider sustainability issues and to develop non-financial measures of performance in addition to traditional ones. Generally, sustainable development is considered as a critical goal for organisations due to its impact on achieving long-term competitiveness ( Hart, 2005 ; Pfeffer, 2010 ) and sustainability has made firms rethink their strategies and situation in the market ( Lubin and Esty, 2010 ; Lee and Lam, 2012 ). The sections below elaborate each of the sustainability dimensions. In addition, Tables III and VI are provided in Sections 5.1 and 5.3 to summarise the key sustainability performance indicators in the context of RL.

3.1 Environmental performance and measurement

Judge and Douglas (1998) described the environmental performance of an organisation as its commitment to environmental excellence in order to meet expectations of society regarding environmental concerns. Environmental performance of an organisation is regarded as its capability to contribute to reductions in air and water pollution and solid waste, and its ability to reduce consumption of harmful, hazardous, and toxic materials and the frequency of environmental accidents ( Zhu et al. , 2008 ). Maxwell and Van der Vorst (2003) mentioned that environmental performance of an organisation can be measured by several indicators such as reduction in energy and material consumption, decrease in air and water pollution and minimisation or elimination of waste generation and use of toxic and harmful materials.

3.2 Economic performance and measurement

The economic performance of an organisation mainly focuses on its profitability and growth ( Judge and Douglas, 1998 ). Daugherty et al. (2005) indicated that the economic performance of RL can be evaluated by using indicators such as recapturing value from products, cost containment, reduction in inventory investment, and improved profitability and labour productivity.

Diabat et al. (2013) categorised economic practices into those that contribute to positive or negative economic performance. They defined benefits obtained through GSCM practices such as cost reduction in purchasing materials, energy consumption, and waste treatment, and reduction of discharge and environmental accidents as positive economic contributors. On the other hand, they defined costs related to the adoption of GSCM practices including costs of investment and purchasing environmentally friendly materials, operational and training cost as negative economic outcomes. While it may seem that adopting GSCM practices is costly and has a negative impact on economic performance in the short time, it can contribute to improvement in other performance in the long term ( Diabat et al. , 2013 ).

3.3 Social performance and measurement

Social performance is defined as “a business organisation’s configuration of principles of social responsibility, processes of social responsiveness, and policies, programs and observable outcomes as they relate to the firm’s societal relationships” ( Wood, 1991 , p. 693). Social performance refers to a company’s apparent engagement with issues related to social responsibility ( Wood, 1991 ) such as quality of management, health and safety issues, wages and benefits, equal opportunities policy, training/education, child labour, forced labour, freedom of association, and human rights and services ( Dixon et al. , 2005 ; DETR, 1999 ). Safety and health issues, disturbance, access and equity were defined as social indicators by DETR (1999) . Sarkis et al. (2010) examined some social indicators such as internal human resources, external population, stakeholder participation and macro social issues. Researchers have suggested that the social aspect of sustainability is underexplored and worthy of further study ( Seuring and Müller, 2008 ; Gold et al. , 2010 ; Seuring, 2013 ).

4. Research methodology

The content analysis method was adopted for conducting the literature review in this paper due to its suitability for observational research and the ability to systematically evaluate the symbolic content of all forms of recorded documents ( Kolbe and Burnett, 1991 ). The content analysis method also helps researchers to identify and analyse the literature to form different categories ( Li and Cavusgil, 1995 ) which can contribute to developing a realm of research opportunities ( Berelson, 1952 ; Kolbe and Burnett, 1991 ).

This review only includes the papers published in scholarly journals and conferences in English between 1990 and 2019. This excludes the articles published in other languages. Databases were used to search for related articles, including Google Scholar (scholar.google.com.au), Science Direct ( www.sciencedirect.com ), Scopus ( www.scopus.com ), Emerald ( www.emeraldinsight.com ), Taylor & Francis (taylorandfrancis.com), Springer ( www.springer.com/gp ), Web of Science ( www.webofknowledge.com ) and ProQuest ( www.proquest.com ). The keywords used for the search were “Reverse Logistics”, “Sustainability”, “Sustainability performance”, “Sustainable development” and “Performance evaluation”. The keywords were applied to the title and abstract in the search and sorted by relevance. Articles that have focused on RL network design and modelling were not included if they do not consider the implementation of RL. In total, 416 papers were collected and after checking the content and relevance of papers, 43 papers were selected and reviewed.

The annual distribution of selected papers is shown in Figure 2 . From 1990 to 2004, no articles have been published on exploring the relationship between RL and sustainability performance. There was a peak in 2013 with seven papers published in the year. Since then, the annual publication number has maintained at a relatively high level due to the increasing interest of researchers in this subject.

The number of articles published by different journals is shown in Table I . Among them, the International Journal of Production Economics is the leading journal with seven papers, followed by the Journal of Cleaner Production with three papers and International Journal of Physical Distribution & Logistics with two papers. The rest of the papers are distributed in other journals. The selected papers were classified into three categories: papers investigating RL from the perspective of GSCM and sustainability performance; papers evaluating RL performance in general without considering the RL processes and disposition options; and papers focusing on different RL disposition options and sustainability performance.

5. Discussion and findings

5.1 rl and sustainable development in the context of gscm.

The natural environment has become a challenging issue for business organisations due to global environmental problems and climate change. In response, organisations have been trying to minimise their impact on the environment ( Beamon, 1999 ). The concept of a green supply chain reflects the responsibility that a firm has towards the environment from purchasing raw materials up to final use and disposal of its products ( Hart, 1997 ). The aim of the green supply chain is to eliminate or minimise waste of materials and energy and negative environmental impacts through all steps of a product’s life cycle ( Hervani et al. , 2005 ). RL is considered as one of the green supply chain practices and some scholars investigated the effect of RL from the perspective of the GSCM along with other practices on different aspects of sustainability and performance outcomes.

Some studies claim a positive relationship between adopting RL and economic performance ( Rao and Holt, 2005 ; Tippayawong et al. , 2015 ). For example, the first empirical study carried out by Rao and Holt (2005) evaluated potential links between RL and improving competitiveness and economic performance amongst a sample of leading-edge ISO14001 certified companies in South East Asia. This research illustrated that greening the inbound function as well as the production phase resulted in greening the outbound phase, which led to significant improvements in competitiveness and economic performance. In another study, the positive influence of RL as one of the green logistics practices on Thai Electronic firms’ financial performance was investigated ( Tippayawong et al. , 2015 ). Other studies found that, in addition to economic performance outcomes, adopting RL along with other GSCM practices results in positive performance outcomes in social and operational areas (e.g. Eltayeb et al. (2010) .

While there are several studies investigating the relationship between RL and other GSCM practices and performance outcomes, the findings are not conclusive as they differ across several industries. While Younis et al. (2016) found a significant positive relationship between RL and social performance, Geng et al. (2017) found no relationship between the two. Contrastingly, Geng et al. (2017) and Diabat et al. (2013) found a positive connection between RL and environmental performance, while Younis et al. (2016) found no such relationship. Wu et al. (2015) claimed that the recovery and recycling system had the most significant effect on economic performance, while Schoenherr (2012) found that recycling does not have any significant effect on economic performance. Table II presents the papers that investigated the effect of RL in the context of GSCM on each dimension of the triple-bottom-line sustainability performance, and Table III shows the relevant sustainability indicators. Table IV is a combination of Tables II and III to provide a holistic picture of RL and its respective impact on each dimension of the sustainability performance in the perspective of GSCM through relevant indicators.

5.2 RL and sustainable development

RL can make a significant contribution to improving the sustainability performance of firms through, for example, its impact on cost savings ( Jack et al. , 2010 ); increased revenue from sales of recovered and remanufactured products ( Mollenkopf and Closs, 2005 ); improved customer satisfaction by acting in a socially and environmentally responsible manner ( Glenn Richey et al. , 2005 ; Li and Olorunniwo, 2008 ); improved customer loyalty by paying more attention to faulty products ( Aitken and Harrison, 2013 ); and its positive effect on climate change and global warming by taking back products and reducing their carbon footprint ( Carter and Rogers, 2008 ).

Efficient and sustainable RL can create competitive advantage through cost savings in procurement, inventory carrying, distribution and transportation ( Li and Olorunniwo, 2008 ; Srivastava and Srivastava, 2006 ; Kannan et al. , 2009 ), positive impact on environmental performance ( Huang et al. , 2010 ) and improving corporate image ( Carter and Ellram, 1998 ). In order to ensure sustainable RL, firms have to continuously monitor and evaluate their RL performance. However, only a small number of studies consider sustainability issues from the RL point of view and examine their possible interrelations. It would be beneficial to investigate the relationship between RL and sustainable development ( Govindan, Soleimani and Kannan, 2015 ; Govindan and Soleimani, 2017 ). In addition, the social aspects of sustainability, especially their application to RL, are less explored and there is a need for research ( Vahabzadeh and Yusuff, 2015 ; Sarkis et al. , 2010 ; Geng et al. , 2017 ; Wang et al. , 2017 ).

Implementing RL has been shown to have significant impacts on organisations’ environmental and economic performance ( Ye et al. , 2013 ; Huang and Yang, 2014 ; Huang et al. , 2015 ). Wanjiku and Mwangangi (2019) investigated the influence of RL on the performance of the food and beverage industry in Kenya. de Oliveira Neto and de Sousa (2014) investigated the implementation of RL in a supermarket business using observations and semi-structured interviews and found that the supermarket gained both environmental and economic advantages. Ye et al. (2013) also reported RL advantages in environmental and economic outcomes in their study of Chinese manufacturing firms with a further study in Taiwan, demonstrating RL’s positive effect on environmental and economic performance ( Huang et al. , 2015 ).

In order to stimulate research related to social sustainability and RL in the literature, Sarkis et al. (2010) developed a profile of RL for social sustainability by referring to practical examples from industries to identify the potential social benefits of RL. They developed four categories: internal human resources (practices associated with employment stability, health and safety); external population (human, productive and community capital); stakeholder participation (information provision and stakeholder influence issues); and macro social issues (socio-economic and socio-environmental performance).

In another study, Nikolaou et al. (2013) proposed an integrated model according to the triple-bottom-line performance indicators to measure the corporate social responsibility of RL. There are a few studies that consider social criteria to evaluate RL performance ( Jindal and Sangwan, 2013 ; Agrawal et al. , 2016b ; Ahmed et al. , 2016 ). Jindal and Sangwan (2013) developed a model to evaluate RL network models based on the triple bottom line of sustainability. They utilised fuzzy AHP approach to compute the weight of economic, environmental and social criteria and then used fuzzy TOPSIS to rank the RL network alternatives. After analysing the results from a case in the automobile industry, they found that economic criteria had the highest weight amongst other criteria. Agrawal et al. (2016b) also found that economic performance had the highest importance in evaluating RL performance, followed by environmental and social performance. Most previous studies have focused on evaluating RL performance in general without considering the processes associated with RL. In particular, little attention has been given to the disposition decisions in RL ( Agrawal et al. , 2016a ; Khor et al. , 2016 ).

5.3 RL disposition options and sustainable development

Since there are different disposition options of RL with different impact on a company’s sustainable development, some scholars explored the impact of RL disposition options on different aspects of sustainability performance in order to present an approach for selecting the appropriate one ( Skinner et al. , 2008 ; Agrawal et al. , 2016a ; Ahmed et al. , 2016 ; Khor et al. , 2016 ; Jindal and Sangwan, 2016 ). For example, Haji Vahabzadeh et al. (2015) examined the impact of RL disposition options on only one of the sustainability dimensions, i.e. environmental dimension. They considered six disposition options and five environmental indicators to analyse and rank the influences of each RL disposition options on each environmental indicator by using the FUZZY_VIKOR method. They found that disposal and reselling the returned products were the best and worst disposition options, respectively. However, the final conclusion could have been more compelling if the economic and social dimensions of RL had also been considered and analysed.

Some scholars investigated the economic performance of RL implementation and disposition options as well as environmental performance ( Ye et al. , 2013 ; Huang and Yang, 2014 ; Khor et al. , 2016 ). For instance, Khor et al. (2016) studied the effect of RL disposition options (repair, recondition, remanufacture, recycle and disposal) on profitability and sales growth as well as environmental performance in Malaysian electrical and electronic equipment manufacturing firms. They considered the institutional theory and identified the effect of regulatory and ownership pressure on the relationship between disposition options and business performance. The study revealed that in the absence of regulatory pressure, only repair and recycling were profitable for these organisations while remanufacturing had a significant impact on sales growth. Also, it should be noted that ownership pressure can create improvements in all aspects of performance, especially for product recondition and remanufacturing activities. Overall, they concluded that RL implementation could contribute to improvements in business performance, especially in the presence of institutional pressures.

The effect of different disposition strategies of RL on economic and operational performance was investigated in another study by Skinner et al. (2008) . They developed a conceptual model to investigate the effect of different disposition strategies on strategic performance (economic and operational performance). They also explored the role of returns policy in the customer’s shopping decisions and the influence of resource commitment (technological, managerial and financial resources) as a moderator. The results of this research illustrated that only destroying and recycling strategies impact on RL performance outcomes directly from the operational responsiveness aspect. While destroying returned goods had a positive effect on operational responsiveness, recycling had a negative influence. This study was limited to economic and operational factors.

Some scholars have utilised multi-criteria decision-making (MCDM) methods for evaluating RL networks and dispositions options ( Jindal and Sangwan, 2013 ; Jindal and Sangwan, 2016 ; Agrawal et al. , 2016a ). A fuzzy MCDM framework was developed by Jindal and Sangwan (2016) in order to select the product disposition process. In this study, the evaluation of different types of disposition options (repair, refurbishing, remanufacturing, cannibalising and recycling) was conducted according to operating cost, value-added recovery, environmental impact, market demand, technical/operational feasibility and corporate responsibility. Fuzzy AHP and fuzzy TOPSIS were utilised to calculate the weight of evaluation criteria and ranking the disposition options, respectively. After conducting a case example, they found that operating cost had the highest importance, followed by value-added recovery, market demand, technical/operational feasibility, environmental impact and corporate social responsibility. By considering these results, repair was the best option due to the low operating cost (repair needs low initial investment and degree of disassembly), high value-added recovery, high technical/operational feasibility and low environmental impact (repair consumes less resource and produces less waste).

Also, in another study, Agrawal et al. (2016a) presented a fuzzy MCDM framework for selecting the best disposition options in RL among recycling, reuse, remanufacturing, repairing and disposal. According to the literature review and discussion with experts, economic benefits, environmental benefits, corporate social responsibility, stakeholder’s needs and RL resources were determined as main criteria for selecting disposition options.

There are few studies focusing on disposition decisions in RL process but no comprehensive study was found that explored the various disposition options and offered a method for selecting the most appropriate one ( Agrawal et al. , 2016a ). There is a research gap that investigates the impact of different RL disposition options on sustainable development by considering economic, environmental and social measures. For instance, Ahmed et al. (2016) developed a model to evaluate and select the best end-of-life vehicles (ELVs) management alternatives considering sustainable criteria (economic, environmental, social and technology). The results show that recycling was the best option in this particular industry. Financial benefits as sub-criteria in the economic dimension were the most important criteria in selecting the best ELVs management alternatives. They mentioned that it would be better if they collected data from multiple industries.

As mentioned before, reuse, repair, remanufacturing, recycling and disposal are the common disposition options in RL and some scholars have investigated the effect of each of them on different sustainability aspects separately. According to the critical discussion in Sections 5.2 and 5.3, Tables V and VI are derived. The two tables show papers that investigated the RL system in general or disposition options and their effects on each dimension of the triple-bottom-line sustainability performance and their relevant sustainability indicators, respectively. Further, Table VII combines Tables V and VI to show a holistic picture of the RL system and disposition options and their respective impact on each dimension of the sustainability performance through relevant indicators.

6. Conclusions

This paper presented a comprehensive review of the literature to evaluate the performance of the RL process based on the three dimensions of sustainability including environmental, economic and social aspects. The content analysis approach was adopted to systematically collect the relevant information from the papers published in academic journals and conferences from the period of 1990–2019. The findings of the review show that when RL is investigated in the context of GSCM, it is studied as a single factor without considering the relationship between the various RL processes and ignoring the different disposition options and their possible performance outcomes. Also, it is compared to other GSCM practices with more attention being paid to its environmental performance and contributions to economic and social benefits being overlooked. Furthermore, only a small number of studies have investigated RL in the context of sustainability and their interrelationship. There is a need to examine the relationship between RL and sustainable development. In addition, the social aspect of sustainability of RL has been largely overlooked.

Moreover, most of the previous studies have focused on evaluating RL performance in general without considering the RL process. While product disposition is a key component of RL, little attention is given to the disposition decisions in RL and their potential impact on sustainability performance. Since there are different disposition options during the RL process, an evaluation of how each disposition option would impact on sustainability performance would enable firms to make informed decisions on choosing the appropriate disposition options. Making an appropriate disposition decision leads to extending the product’s life and can achieve many goals of sustainable development. Future research should focus on finding empirical evidence on how each of the disposition options may impact on the sustainability performance, examining all disposition options in the same context, comparing the differences between different industries and using the triple-bottom-line approach for measuring sustainability performance.

Fundamental flow of RL and forward logistics processes

Annual distribution of papers across the period of the study

Number of articles published by main journals

RL and sustainability performance in the perspective of GSCM

Sustainability indicators (RL and sustainability performance in the perspective of GSCM)

A holistic picture of RL and its respective impact on each dimension of the sustainability performance in the perspective of GSCM through relevant indicators

Sustainability indicators (the RL system and disposition options and sustainability performance)

A holistic picture of the RL system and disposition options and their respective impact on each dimension of the sustainability performance through relevant indicators

Note: The number in each cell refers to the number of articles researched

Abdel-Baset , M. , Chang , V. and Gamal , A. ( 2019 ), “ Evaluation of the green supply chain management practices: a novel neutrosophic approach ”, Computers in Industry , Vol. 108 , pp. 210 - 220 .

Agrawal , S. , Singh , R.K. and Murtaza , Q. ( 2015 ), “ A literature review and perspectives in reverse logistics ”, Resources, Conservation and Recycling , Vol. 97 , pp. 76 - 92 .

Agrawal , S. , Singh , R.K. and Murtaza , Q. ( 2016a ), “ Disposition decisions in reverse logistics by using AHP-fuzzy TOPSIS approach ”, Journal of Modelling in Management , Vol. 11 No. 4 , pp. 932 - 948 .

Agrawal , S. , Singh , R.K. and Murtaza , Q. ( 2016b ), “ Triple bottom line performance evaluation of reverse logistics ”, Competitiveness Review , Vol. 26 No. 3 , pp. 289 - 310 .

Ahmed , S. , Ahmed , S. , Shumon , M.R.H. , Quader , M.A. , Cho , H.M. and Mahmud , M.I. ( 2016 ), “ Prioritizing strategies for sustainable end-of-life vehicle management using combinatorial multi-criteria decision making method ”, International Journal of Fuzzy Systems , Vol. 18 No. 3 , pp. 448 - 462 .

Aitken , J. and Harrison , A. ( 2013 ), “ Supply governance structures for reverse logistics systems ”, International Journal of Operations & Production Management , Vol. 33 No. 6 , pp. 745 - 764 .

Álvarez-gil , M.J. , Berrone , P. , Husillos , F.J. and Lado , N. ( 2007 ), “ Reverse logistics, stakeholders’ influence, organizational slack, and managers’ posture ”, Journal of Business Research , Vol. 60 No. 5 , pp. 463 - 473 .

Atasu , A. , Toktay , L.B. and Van Wassenhove , L.N. ( 2013 ), “ How collection cost structure drives a manufacturer’s reverse channel choice ”, Production and Operations Management , Vol. 22 No. 5 , pp. 1089 - 1102 .

Azevedo , S.G. , Carvalho , H. and Cruz Machado , V. ( 2011 ), “ The influence of green practices on supply chain performance: a case study approach ”, Transportation Research Part E: Logistics and Transportation Review , Vol. 47 No. 6 , pp. 850 - 871 .

Bahrami , B. and Jafari , P. ( 2019 ), “ Paper recycling, directions to sustainable landscape ”, International Journal of Environmental Science and Technology , pp. 1 - 12 .

Beamon , B.M. ( 1999 ), “ Designing the green supply chain ”, Logistics Information Management , Vol. 12 No. 4 , pp. 332 - 342 .

Berelson , B. ( 1952 ), “ Content analysis in communication research ”, The Free Press , Glencoe, IL .

Bernon , M. and Cullen , J. ( 2007 ), “ An integrated approach to managing reverse logistics ”, International Journal of Logistics: Research and Applications , Vol. 10 No. 1 , pp. 41 - 56 .

Blackburn , J.D. , Guide , V.D.R. Jr , Souza , G.C. and Van Wassenhove , L.N. ( 2004 ), “ Reverse supply chains for commercial returns ”, California Management Review , Vol. 46 No. 2 , pp. 6 - 22 .

Carter , C.R. and Ellram , L.M. ( 1998 ), “ Reverse logistics: a review of the literature and framework for future investigation ”, Journal of Business Logistics , Vol. 19 No. 1 , pp. 85 - 102 .

Carter , C.R. and Rogers , D.S. ( 2008 ), “ A framework of sustainable supply chain management: moving toward new theory ”, International Journal of Physical Distribution & Logistics Management , Vol. 38 No. 5 , pp. 360 - 387 .

Chen , Y.J. , Wu , T.H. and Chen , Y.L. ( 2009 ), “ The recycling business for sustainability in Taiwan ”, European Business Review , Vol. 21 No. 5 , pp. 403 - 417 .

Corbett , C.J. and Klassen , R.D. ( 2006 ), “ Extending the horizons: environmental excellence as key to improving operations ”, Manufacturing & Service Operations Management , Vol. 8 No. 1 , pp. 5 - 22 .

Daugherty , P.J. , Richey , R.G. , Genchev , S.E. and Chen , H. ( 2005 ), “ Reverse logistics: superior performance through focused resource commitments to information technology ”, Transportation Research Part E: Logistics and Transportation Review , Vol. 41 No. 2 , pp. 77 - 92 .

De Brito , M.P. and Dekker , R. ( 2002 ), “ Reverse logistics-a framework ”, Econometric Institute Report EI , Erasmus School of Economics , Rotterdam , pp. 2002 - 2038 .

De Oliveira Neto , G.C. and De Sousa , W.C. ( 2014 ), “ Economic and environmental advantage evaluation of the reverse logistic implementation in the supermarket retail ”, in Grabot , B. , Vallespir , B. , Gomes , S. , Bouras , A. and Kiritsis , D. (Eds), Advances in Production Management Systems. Innovative and Knowledge-Based Production Management in a Global-Local World: IFIP WG 5.7 International Conference, APMS 2014, Ajaccio, France, September 20-24, Proceedings, Part II , Springer , Berlin and Heidelberg , pp. 197 - 204 .

DETR ( 1999 ), “ Sustainable distribution: a strategy ”, Office of the Deputy Prime Minister (ODPM) .

Diabat , A. , Khodaverdi , R. and Olfat , L. ( 2013 ), “ An exploration of green supply chain practices and performances in an automotive industry ”, International Journal of Advanced Manufacturing Technology , Vol. 68 Nos 1-4 , pp. 949 - 961 .

Dixon , R. , Mousa , G.A. and Woodhead , A. ( 2005 ), “ The role of environmental initiatives in encouraging companies to engage in environmental reporting ”, European Management Journal , Vol. 23 No. 6 , pp. 702 - 716 .

Elkington , J. ( 2001 ), “ The triple bottom line for 21st century business ”, The Earthscan Reader in Business and Sustainable Development , Earthscan , London , pp. 20 - 43 .

Eltayeb , T.K. , Zailani , S. and Filho , W.L. ( 2010 ), “ Green business among certified companies in Malaysia towards environmental sustainability: benchmarking on the drivers, initiatives and outcomes ”, International Journal of Environmental Technology and Management , Vol. 12 No. 1 , pp. 95 - 125 .

Eltayeb , T.K. , Zailani , S. and Ramayah , T. ( 2011 ), “ Green supply chain initiatives among certified companies in Malaysia and environmental sustainability: investigating the outcomes ”, Resources, Conservation and Recycling , Vol. 55 No. 5 , pp. 495 - 506 .

Flapper , S.D. ( 2003 ), “ Product recovery strategies ”, Business Aspects of Closed-loop Chains: Exploring the Issues , Carnegie Bosch Institute, Carnegie Mellon University Press , Pittsburgh, PA , pp. 71 - 92 .

Fleischmann , M. , Krikke , H.R. , Dekker , R. and Flapper , S.D.P. ( 2000 ), “ A characterisation of logistics networks for product recovery ”, Omega , Vol. 28 No. 6 , pp. 653 - 666 .

Fleischmann , M. , Bloemhof-Ruwaard , J.M. , Dekker , R. , Van Der Laan , E. , Van Nunen , J.A. and Van Wassenhove , L.N. ( 1997 ), “ Quantitative models for reverse logistics: a review ”, European Journal of Operational Research , Vol. 103 No. 1 , pp. 1 - 17 .

Geng , R. , Mansouri , S.A. and Aktas , E. ( 2017 ), “ The relationship between green supply chain management and performance: a meta-analysis of empirical evidences in Asian emerging economies ”, International Journal of Production Economics , Vol. 183 No. 1 , pp. 245 - 258 .

Glenn Richey , R. , Genchev , S.E. and Daugherty , P.J. ( 2005 ), “ The role of resource commitment and innovation in reverse logistics performance ”, International Journal of Physical Distribution & Logistics Management , Vol. 35 No. 4 , pp. 233 - 257 .

Gold , S. , Seuring , S. and Beske , P. ( 2010 ), “ The constructs of sustainable supply chain management – a content analysis based on published case studies ”, Progress in Industrial Ecology: An International Journal , Vol. 7 No. 2 , pp. 114 - 137 .

Govindan , K. and Soleimani , H. ( 2017 ), “ A review of reverse logistics and closed-loop supply chains: a journal of cleaner production focus ”, Journal of Cleaner Production , Vol. 142 No. 1 , pp. 371 - 384 .

Govindan , K. , Khodaverdi , R. and Vafadarnikjoo , A. ( 2015 ), “ Intuitionistic fuzzy based DEMATEL method for developing green practices and performances in a green supply chain ”, Expert Systems with Applications , Vol. 42 No. 20 , pp. 7207 - 7220 .

Govindan , K. , Soleimani , H. and Kannan , D. ( 2015 ), “ Reverse logistics and closed-loop supply chain: a comprehensive review to explore the future ”, European Journal of Operational Research , Vol. 240 No. 3 , pp. 603 - 626 .

Govindan , K. , Azevedo , S.G. , Carvalho , H. and Cruz-Machado , V. ( 2014 ), “ Impact of supply chain management practices on sustainability ”, Journal of Cleaner Production , Vol. 85 No. 15 , pp. 212 - 225 .

Guide , V.D.R. and Wassenhove , L.N. ( 2003 ), Business Aspects of Closed-loop Supply Chains , Carnegie Mellon University Press , Pittsburgh, PA .

Gunasekaran , A. and Spalanzani , A. ( 2012 ), “ Sustainability of manufacturing and services: investigations for research and applications ”, International Journal of Production Economics , Vol. 140 No. 1 , pp. 35 - 47 .

Haji Vahabzadeh , A. , Asiaei , A. and Zailani , S. ( 2015 ), “ Green decision-making model in reverse logistics using FUZZY-VIKOR method ”, Resources, Conservation and Recycling , Vol. 103 No. 10 , pp. 125 - 138 .

Hart , A. , Clift , R. , Riddlestone , S. and Buntin , J. ( 2005 ), “ Use of life cycle assessment to develop industrial ecologies – a case study: graphics paper ”, Process Safety and Environmental Protection , Vol. 83 No. 4 , pp. 359 - 363 .

Hart , S.L. ( 1997 ), “ Beyond greening: strategies for a sustainable world ”, Harvard Business Review , Vol. 75 No. 1 , pp. 66 - 77 .

Hart , S.L. ( 2005 ), “ Innovation, creative destruction and sustainability ”, Research-Technology Management , Vol. 48 No. 5 , pp. 21 - 27 .

Hazen , B.T. ( 2011 ), “ Strategic reverse logistics disposition decisions: from theory to practice ”, International Journal of Logistics Systems and Management , Vol. 10 No. 3 , pp. 275 - 292 .

Hervani , A.A. , Helms , M.M. and Sarkis , J. ( 2005 ), “ Performance measurement for green supply chain management ”, Benchmarking: An International Journal , Vol. 12 No. 4 , pp. 330 - 353 .

Huang , Y. , Wu , Y. , Chang , N. and Boulanger , N. ( 2010 ), “ Reverse logistics activities, the task environment and performance: Taiwanese 3C retailers ”, International Conference on Service Operations and Logistics and Informatics, IEEE , Qingdao , 15-17 July , pp. 258 - 263 .

Huang , Y.-C. and Yang , M.-L. ( 2014 ), “ Reverse logistics innovation, institutional pressures and performance ”, Management Research Review , Vol. 37 No. 7 , pp. 615 - 641 .

Huang , Y.C. , Rahman , S. , Wu , Y.C.J. and Huang , C.J. ( 2015 ), “ Salient task environment, reverse logistics and performance ”, International Journal of Physical Distribution and Logistics Management , Vol. 45 Nos 9/10 , pp. 979 - 1006 .

Hubbard , G. ( 2009 ), “ Measuring organizational performance: beyond the triple bottom line ”, Business Strategy and the Environment , Vol. 18 No. 3 , pp. 177 - 191 .

Jack , E.P. , Powers , T.L. and Skinner , L. ( 2010 ), “ Reverse logistics capabilities: antecedents and cost savings ”, International Journal of Physical Distribution & Logistics Management , Vol. 40 No. 3 , pp. 228 - 246 .

Jindal , A. and Sangwan , K.S. ( 2013 ), “ An integrated fuzzy multi-criteria evaluation of sustainable reverse logistics network models ”, IEEE International Conference on Fuzzy Systems , Hyderabad , 1-7 July .

Jindal , A. and Sangwan , K.S. ( 2016 ), “ A fuzzy-based decision support framework for product recovery process selection in reverse logistics ”, International Journal of Services and Operations Management , Vol. 25 No. 4 , pp. 413 - 439 .

Judge , W.Q. and Douglas , T.J. ( 1998 ), “ Performance implications of incorporating natural environmental issues into the strategic planning process: an empirical assessment ”, Journal of Management Studies , Vol. 35 No. 2 , pp. 241 - 262 .

Kang , D. ( 2015 ), “ Environmental evaluation of non-alcoholic single-serve PET beverage bottles in the state of California using life cycle assessment and system dynamics ”, PhD, Michigan State University, Ann Arbor, MI .

Kannan , G. , Pokharel , S. and Kumar , P.S. ( 2009 ), “ A hybrid approach using ISM and fuzzy TOPSIS for the selection of reverse logistics provider ”, Resources, Conservation and Recycling , Vol. 54 No. 1 , pp. 28 - 36 .

Keh , P. , Rodhain , F. , Meissonier , R. and Llorca , V. ( 2012 ), “ Financial performance, environmental compliance, and social outcomes: the three challenges of reverse logistics: case study of IBM Montpellier ”, Supply Chain Forum: An International Journal , Vol. 13 No. 3 , pp. 26 - 38 .

Khor , K.S. , Udin , Z.M. , Ramayah , T. and Hazen , B.T. ( 2016 ), “ Reverse logistics in Malaysia: the contingent role of institutional pressure ”, International Journal of Production Economics , Vol. 175 No. 5 , pp. 96 - 108 .

Kolbe , R.H. and Burnett , M.S. ( 1991 ), “ Content-analysis research: an examination of applications with directives for improving research reliability and objectivity ”, Journal of Consumer Research , Vol. 18 No. 2 , pp. 243 - 250 .

Kolk , A. and Pinkse , J. ( 2008 ), “ A perspective on multinational enterprises and climate change: learning from ‘an inconvenient truth?’ ”, Journal of International Business Studies , Vol. 39 No. 8 , pp. 1359 - 1378 .

Kumar , S. and Putnam , V. ( 2008 ), “ Cradle to cradle: reverse logistics strategies and opportunities across three industry sectors ”, International Journal of Production Economics , Vol. 115 No. 2 , pp. 305 - 315 .

Laosirihongthong , T. , Adebanjo , D. and Choon Tan , K. ( 2013 ), “ Green supply chain management practices and performance ”, Industrial Management & Data Systems , Vol. 113 No. 8 , pp. 1088 - 1109 .

Lee , C.K.M. and Lam , J.S.L. ( 2012 ), “ Managing reverse logistics to enhance sustainability of industrial marketing ”, Industrial Marketing Management , Vol. 41 No. 4 , pp. 589 - 598 .

Li , T. and Cavusgil , S.T. ( 1995 ), “ A classification and assessment of research streams in international marketing ”, International Business Review , Vol. 4 No. 3 , pp. 251 - 277 .

Li , X. and Olorunniwo , F. ( 2008 ), “ An exploration of reverse logistics practices in three companies ”, Supply Chain Management: An International Journal , Vol. 13 No. 5 , pp. 381 - 386 .

Lubin , D.A. and Esty , D.C. ( 2010 ), “ The sustainability imperative ”, Harvard Business Review , Vol. 88 No. 5 , pp. 42 - 50 .

Matsumoto , M. ( 2010 ), “ Development of a simulation model for reuse businesses and case studies in Japan ”, Journal of Cleaner Production , Vol. 18 No. 13 , pp. 1284 - 1299 .

Maxwell , D. and Van der Vorst , R. ( 2003 ), “ Developing sustainable products and services ”, Journal of Cleaner Production , Vol. 11 No. 8 , pp. 883 - 895 .

Mollenkopf , D.A. and Closs , D.J. ( 2005 ), “ The hidden value in reverse logistics ”, Supply Chain Management Review , Vol. 9 No. 5 , pp. 34 - 43 .

Murphy , P.R. and Poist , R. ( 1988 ), “ Management of logistical retromovements: an empirical analysis of literature suggestions ”, Journal of the Transportation Research Forum , Vol. 29 No. 1 , pp. 177 - 184 .

Mutha , A. and Pokharel , S. ( 2009 ), “ Strategic network design for reverse logistics and remanufacturing using new and old product modules ”, Computers & Industrial Engineering , Vol. 56 No. 1 , pp. 334 - 346 .

Nikolaou , I.E. , Evangelinos , K.I. and Allan , S. ( 2013 ), “ A reverse logistics social responsibility evaluation framework based on the triple bottom line approach ”, Journal of Cleaner Production , Vol. 56 No. 1 , pp. 173 - 184 .

Nußholz , J.L. and Whalen , K. ( 2019 ), “ Financial assessment of reusing materials in buildings: comparing financial potential of wood, concrete, and glass reuse ”, IOP Conference Series: Earth and Environmental Science, IOP Publishing , Brussels , 5-7 February .

O’Connell , M.W. , Hickey , S.W. and Fitzpatrick , C. ( 2013 ), “ Evaluating the sustainability potential of a white goods refurbishment program ”, Sustainability Science , Vol. 8 No. 4 , pp. 529 - 541 .

Oliveira , M.C. and Magrini , A. ( 2017 ), “ Life cycle assessment of lubricant oil plastic containers in Brazil ”, Sustainability (Switzerland) , Vol. 9 No. 4, pp. 576 - 592 .

Oliveira Neto , G.C. and Correia , J.M. ( 2019 ), “ Environmental and economic advantages of adopting reverse logistics for recycling construction and demolition waste: a case study of Brazilian construction and recycling companies ”, Waste Management & Research , Vol. 37 No. 2 , pp. 176 - 185 .

Pfeffer , J. ( 2010 ), “ Building sustainable organizations: the human factor ”, The Academy of Management Perspectives , Vol. 24 No. 1 , pp. 34 - 45 .

Pochampally , K.K. and Gupta , S.M. ( 2004 ), “ A business-mapping approach to multi-criteria group selection of collection centers and recovery facilities ”, 2004 IEEE International Symposium on Electronics and the Environment, Conference Record, IEEE , Scottsdale, AZ , 10-13 May , pp. 249 - 254 .

Pokharel , S. and Mutha , A. ( 2009 ), “ Perspectives in reverse logistics: a review ”, Resources, Conservation and Recycling , Vol. 53 No. 4 , pp. 175 - 182 .

Prahinski , C. and Kocabasoglu , C. ( 2006 ), “ Empirical research opportunities in reverse supply chains ”, Omega , Vol. 34 No. 6 , pp. 519 - 532 .

Rao , P. and Holt , D. ( 2005 ), “ Do green supply chains lead to competitiveness and economic performance? ”, International Journal of Operations & Production Management , Vol. 25 No. 9 , pp. 898 - 916 .

Rogers , D.S. and Tibben-Lembke , R. ( 1999 ), “ Going backwards: reverse logistics trends and practices ”, RLEC Press , Pittsburgh, PA , p. 2 .

Sabharwal , S. and Garg , S. ( 2013 ), “ Determining cost effectiveness index of remanufacturing: a graph theoretic approach ”, International Journal of Production Economics , Vol. 144 No. 2 , pp. 521 - 532 .

Sarkis , J. , Helms , M.M. and Hervani , A.A. ( 2010 ), “ Reverse logistics and social sustainability ”, Corporate Social Responsibility and Environmental Management , Vol. 17 No. 6 , pp. 337 - 354 .

Schoenherr , T. ( 2012 ), “ The role of environmental management in sustainable business development: a multi-country investigation ”, International Journal of Production Economics , Vol. 140 No. 1 , pp. 116 - 128 .

Seuring , S. ( 2013 ), “ A review of modeling approaches for sustainable supply chain management ”, Decision Support Systems , Vol. 54 No. 4 , pp. 1513 - 1520 .

Seuring , S. and Müller , M. ( 2008 ), “ From a literature review to a conceptual framework for sustainable supply chain management ”, Journal of Cleaner Production , Vol. 16 No. 15 , pp. 1699 - 1710 .

Skinner , L.R. , Bryant , P.T. and Glenn Richey , R. ( 2008 ), “ Examining the impact of reverse logistics disposition strategies ”, International Journal of Physical Distribution & Logistics Management , Vol. 38 No. 7 , pp. 518 - 539 .

Srivastava , S.K. and Srivastava , R.K. ( 2006 ), “ Managing product returns for reverse logistics ”, International Journal of Physical Distribution & Logistics Management , Vol. 36 No. 7 , pp. 524 - 546 .

Stock , J. , Speh , T. and Shear , H. ( 2002 ), “ Many happy (product) returns ”, Harvard Business Review , Vol. 80 No. 7 , pp. 16 - 17 .

Stock , J.R. ( 1998 ), “ Development and implementation of reverse logistics programs ”, Annual Conference Proceedings, Council of Logistics Management , Oak Brook, IL , pp. 579 - 586 .

Székely , F. and Knirsch , M. ( 2005 ), “ Responsible leadership and corporate social responsibility: metrics for sustainable performance ”, European Management Journal , Vol. 23 No. 6 , pp. 628 - 647 .

Thierry , M. , Salomon , M. , Van Nunen , J. and Van Wassenhove , L. ( 1995 ), “ Strategic issues in product recovery management ”, California Management Review , Vol. 37 No. 2 , pp. 114 - 135 .

Tibben-Lembke , R.S. and Rogers , D.S. ( 2002 ), “ Differences between forward and reverse logistics in a retail environment ”, Supply Chain Management: An International Journal , Vol. 7 No. 5 , pp. 271 - 282 .

Tippayawong , K.Y. , Tiwaratreewit , T. and Sopadang , A. ( 2015 ), “ Positive influence of green supply chain operations on Thai electronic firms’ financial performance ”, Procedia Engineering , Vol. 118 No. 4 , pp. 683 - 690 .

Vahabzadeh , A.H. and Yusuff , R.B.M. ( 2015 ), “ A content analysis in reverse logistics: a review ”, Journal of Statistics and Management Systems , Vol. 18 No. 4 , pp. 329 - 379 .

Vahabzadeh , A.H. , Asiaei , A. and Zailani , S. ( 2015 ), “ Green decision-making model in reverse logistics using FUZZY-VIKOR method ”, Resources Conservation and Recycling , Vol. 103 No. 10 , pp. 125 - 138 .

Wang , J.-J. , Chen , H. , Rogers , D.S. , Ellram , L.M. and Grawe , S.J. ( 2017 ), “ A bibliometric analysis of reverse logistics research (1992-2015) and opportunities for future research ”, International Journal of Physical Distribution & Logistics Management , Vol. 47 No. 8 , pp. 666 - 687 .

Wanjiku , E. and Mwangangi , P. ( 2019 ), “ Influence of procurement best practices on the performance of food and beverage manufacturing firms in Kenya ”, International Journal of Supply Chain and Logistics , Vol. 3 No. 1 , pp. 26 - 49 .

Wibowo , S. , Deng , H. and Zhang , X. ( 2014 ), “ Evaluating the performance of e-waste recycling programs using fuzzy multiattribute group decision making model ”, Proceedings of the 2014 9th IEEE Conference on Industrial Electronics and Applications , Hangzhou , 9-11 June , pp. 1989 - 1994 .

Wood , D.J. ( 1991 ), “ Corporate social performance revisited ”, Academy of Management Review , Vol. 16 No. 4 , pp. 691 - 718 .

Wu , K.J. , Liao , C.J. , Tseng , M.L. and Chiu , A.S.F. ( 2015 ), “ Exploring decisive factors in green supply chain practices under uncertainty ”, International Journal of Production Economics , Vol. 159 , pp. 147 - 157 .

Yalabik , B. , Chhajed , D. and Petruzzi , N.C. ( 2014 ), “ Product and sales contract design in remanufacturing ”, International Journal of Production Economics , Vol. 154 , pp. 299 - 312 .

Ye , F. , Zhao , X. , Prahinski , C. and Li , Y. ( 2013 ), “ The impact of institutional pressures, top managers’ posture and reverse logistics on performance – evidence from China ”, International Journal of Production Economics , Vol. 143 No. 1 , pp. 132 - 143 .

Younis , H. , Sundarakani , B. and Vel , P. ( 2016 ), “ The impact of implementing green supply chain management practices on corporate performance ”, Competitiveness Review , Vol. 26 No. 3 , pp. 216 - 245 .

Yu , Z. , Tianshan , M. and Din , M.F.U. ( 2018 ), “ The impact of reverse logistics on operational performance ”, American Journal of Mechanical and Industrial Engineering , Vol. 3 No. 5 , pp. 99 - 104 .

Zanghelini , G.M. , Cherubini , E. , Orsi , P. and Soares , S.R. ( 2014 ), “ Waste management life cycle assessment: the case of a reciprocating air compressor in Brazil ”, Journal of Cleaner Production , Vol. 70 , pp. 164 - 174 .

Zhu , Q. , Sarkis , J. and Lai , K.-H. ( 2008 ), “ Confirmation of a measurement model for green supply chain management practices implementation ”, International Journal of Production Economics , Vol. 111 No. 2 , pp. 261 - 273 .

Corresponding author

Related articles, all feedback is valuable.

Please share your general feedback

Report an issue or find answers to frequently asked questions

Contact Customer Support

A review of current trends and future directions in reverse logistics research

- Published: 23 March 2023

- Volume 36 , pages 379–408, ( 2024 )

Cite this article

- Raphael Aryee 1 &

- Ebenezer Adaku ORCID: orcid.org/0000-0001-6017-2056 1

1412 Accesses

9 Citations

Explore all metrics

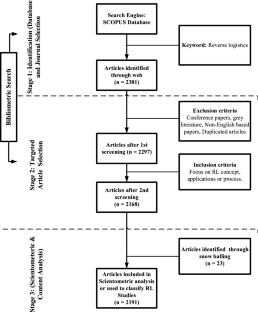

Reverse logistics (RL) studies, in recent times, have gained considerable attention among practitioners and scholars in different geographical regions. This is due to the potential of RL to enhance the economic and environmental performance of firms. Nonetheless, there is a paucity of systematic scientometric studies evaluating all aspects of RL with a direction for future research on the phenomenon. This study attempts to bridge this gap by conducting a scientometric coupled with content analysis of current RL studies. A total of 2191 articles from Scopus database supported by a snowballing approach, from Google scholar, was used to construct science maps. The review unearthed most prolific journals, authorships, article citations, countries, institutions and co-occurrence network of keywords. Besides, a qualitative analysis revealed six RL themes namely: importance, drivers, implementational resources, practices, empirical studies and mathematical modeling. This study serves as an RL reference for both scholars and practitioners. It highlights the status quo and provides pointers for future RL research.

This is a preview of subscription content, log in via an institution to check access.

Access this article

Subscribe and save.

- Get 10 units per month

- Download Article/Chapter or eBook

- 1 Unit = 1 Article or 1 Chapter

- Cancel anytime

Price includes VAT (Russian Federation)

Instant access to the full article PDF.

Rent this article via DeepDyve

Institutional subscriptions

Similar content being viewed by others

Investigating digital transformation technologically enabled solutions in reverse logistics: a systematic review

The Era of Innovation for Sustainability-Oriented Logistics: A Systematic Literature Review of European Studies

The application of big data analytics in optimizing logistics: a developmental perspective review

Abdallah M, Hamdan S, Shabib A (2021) A multi-objective optimization model for strategic waste management master plans. J Clean Prod 284:124714

Article Google Scholar

Abdolazimi O, Esfandarani MS, Salehi M, Shishebori D (2020) Robust design of a multi-objective closed-loop supply chain by integrating on-time delivery, cost, and environmental aspects, case study of a Tire Factory. J Clean Prod 264:121566

Abdulrahman MD, Gunasekaran A, Subramanian N (2014) Critical barriers in implementing reverse logistics in the Chinese manufacturing sectors. Int J Prod Econ 147:460–471

Aćimović S, Mijušković V, Rajić V (2020) The impact of reverse logistics onto green supply chain competitiveness evidence from Serbian consumers. Int J Retail Distrib Manag. https://doi.org/10.1108/IJRDM-04-2019-0142

Afra AP, Behnamian J (2021) Lagrangian heuristic algorithm for green multi-product production routing problem with reverse logistics and remanufacturing. J Manuf Syst 58:33–43

Afum E, Sun BZ, Kusi CLY (2019) Reverse logistics, stakeholder influence and supply chain performance in Ghanaian manufacturing sector. J Supply Chain Manag Syst 8(3):13

Google Scholar

Agrawal S, Singh RK (2019) Analyzing disposition decisions for sustainable reverse logistics: triple bottom line approach. Resour Conserv Recycl 150:104448

Agrawal S, Singh RK, Murtaza Q (2015) A literature review and perspectives in reverse logistics. Resour Conserv Recycl 97:76–92

Akdoğan MŞ, Coşkun A (2012) Drivers of reverse logistics activities: an empirical investigation. Procedia Soc Behav Sci 58:1640–1649

Alkantani M, Ziout A, Salah B, Alatefi M, Abd Elgawad AEE, Badwelan A, Syarif U (2021) An insight into reverse logistics with a focus on collection systems. Sustainability 13(2):548

Anandh G, PrasannaVenkatesan S, Goh M, Mathiyazhagan K (2021) Reuse assessment of WEEE: systematic review of emerging themes and research directions. J Environ Manag 287:112335

Andiç E, Yurt Ö, Baltacıoğlu T (2012) Green supply chains: efforts and potential applications for the Turkish market. Resour Conserv Recycl 58:50–68

Baah C, Opoku-Agyeman D, Acquah ISK, Agyabeng-Mensah Y, Afum E, Faibil D, Abdoulaye FAM (2021) Examining the correlations between stakeholder pressures, green production practices, firm reputation, environmental and financial performance: evidence from manufacturing SMEs. Sustain Prod Consump 27:100–114

Banihashemi S, Tabadkani A, Hosseini MR (2018) Integration of parametric design into modular coordination: a construction waste reduction workflow. Autom Constr 88:1–12

Basri H (2020) Solid waste collection optimization objectives, constraints, modeling approaches, and their challenges toward achieving sustainable development goals. J Clean Prod 277:123557

Bazan E, Jaber MY, Zanoni S (2016) A review of mathematical inventory models for reverse logistics and the future of its modeling: an environmental perspective. Appl Math Model 40(5–6):4151–4178

Article MathSciNet Google Scholar

Bensalem A, Kin V (2019) A bibliometric analysis of reverse logistics from 1992 to 2017. Supply Chain Forum Int J. 20(1):15–28

Barney JB (2002) Strategic management: From informed conversation to academic discipline. Acad Manag Perspect 16(2):53–57

Bittencourt ES, Fontes CHDO, Rodriguez JLM, Filho SÁ, Ferreira AMS (2020) Modeling the socioeconomic metabolism of end-of-life tires using structural equations: a Brazilian case study. Sustainability 12(5):2106

Bouzon M, Govindan K (2015) Reverse logistics as a sustainable supply chain practice for the fashion industry: an analysis of drivers and the Brazilian Case. Sustainable fashion supply chain management. Springer, Cham, pp 85–104

Chapter Google Scholar

Bouzon M, Spricigo R, Rodriguez CM, de Queiroz AA, Cauchick Miguel PA (2015) Reverse logistics drivers: empirical evidence from a case study in an emerging economy. Prod Plann Control 26(16):1368–1385

Cao J, Zhang X, Hu L, Xu J, Zhao Y, Zhou G, Schnoor JL (2018) EPR regulation and reverse supply chain strategy on remanufacturing. Comput Ind Eng 125:279–297

Chakraborty K, Mukherjee K, Mondal S, Mitra S (2021) A systematic literature review and bibliometric analysis based on pricing related decisions in remanufacturing. J Clean Prod 310:127265

Chalmeta R, Santos-deLeón NJ (2020) Sustainable supply chain in the era of industry 4.0 and big data: a systematic analysis of literature and research. Sustainability 12(10):4108

Chan FT, Chan HK, Jain V (2012) A framework of reverse logistics for the automobile industry. Int J Prod Res 50(5):1318–1331

Chileshe N, Rameezdeen R, Hosseini MR (2016) Drivers for adopting reverse logistics in the construction industry: a qualitative study. Eng Constr Arch Manag

Chiou CY, Chen HC, Yu CT, Yeh CY (2012) Consideration factors of reverse logistics implementation-a case study of Taiwan’s electronics industry. Procedia Soc Behav Sci 40:375–381

Çimen M, Sel Ç, Soysal M (2020) An approximate dynamic programming approach for a routing problem with simultaneous pick-ups and deliveries in urban areas. Food supply chains in cities. Palgrave Macmillan, Cham, pp 101–143

Cole C, Gnanapragasam A, Singh J, Cooper T (2018) Enhancing reuse and resource recovery of electrical and electronic equipment with reverse logistics to meet carbon reduction targets. Proc Cirp 69:980–985

Daugherty PJ, Richey RG, Genchev SE, Chen H (2005) Reverse logistics: superior performance through focused resource commitments to information technology. Transp Res Part e Logist Transp Rev 41(2):77–92

Davidavičienė V, Al Majzoub M (2021) Performance of reverse logistics in electronic commerce: a case study from Lebanon and Syria. Transport 36(3):260–282

De Solla Price DJ (1963) Little science, big science. Columbia University Press, New York

Book Google Scholar

Defalque CM, da Silva AF, Marins FAS (2021) Goal programming model applied to waste paper logistics processes. Appl Math Model 98:185–206

Demirel E, Demirel N, Gökçen H (2016) A mixed integer linear programming model to optimize reverse logistics activities of end-of-life vehicles in Turkey. J Clean Prod 112:2101–2113

Dev NK, Shankar R, Swami S (2020) Diffusion of green products in industry 4.0: Reverse logistics issues during design of inventory and production planning system. Int J Prod Econ 223:107519

Duhbacı TB, Özel S, Bulkan S (2020) Water and energy minimization in industrial processes through mathematical programming: a literature review. J Clean Prod 284:124752

Dunne C (2011) The place of the literature review in grounded theory research. Int J Soc Res Methodol 14(2):111–124

Duong QH, Zhou L, Meng M, Van Nguyen T, Ieromonachou P, Nguyen DT (2022) Understanding product returns: a systematic literature review using machine learning and bibliometric analysis. Int J Prod Econ 243:108340

Dutta P, Talaulikar S, Xavier V, Kapoor S (2021) Fostering reverse logistics in India by prominent barrier identification and strategy implementation to promote circular economy. J Clean Prod 294:126241

Eltayeb TK, Zailani SHM (2011) Drivers on the reverse logistics: evidence from Malaysian certified companies. Int J Logist Syst Manag 10(4):375–397

Fleischmann M (2001) Quantitative models for reverse logistics, Lecture Notes in Economics and Mathematical Systems, Vol. 501

Forkan M, Rizvi MM, Chowdhury MAM (2022) Multiobjective reverse logistics model for inventory management with environmental impacts: an application in industry. Intell Syst Appl 14:200078

Giri BC, Glock CH (2017) A closed-loop supply chain with stochastic product returns and worker experience under learning and forgetting. Int J Prod Res 55(22):6760–6778

Govindan K, Bouzon M (2018) From a literature review to a multi-perspective framework for reverse logistics barriers and drivers. J Clean Prod 187:318–337

Govindan K, Paam P, Abtahi AR (2016a) A fuzzy multi-objective optimization model for sustainable RL network design. Ecol Ind 67:753–768

Govindan K, Paam P, Abtahi AR (2016b) A fuzzy multi-objective optimization model for sustainable reverse logistics network design. Ecol Ind 67:753–768

Hansen ZNL, Larsen SB, Nielsen AP, Groth A, Gregersen NG, Ghosh A (2018) Combining or separating forward and reverse logistics. Int J Logist Manag

Hannan MA, Lipu MH, Akhtar M, Begum RA, Al Mamun MA, Hussain A, Basri H (2020) Solid waste collection optimization objectives, constraints, modeling approaches, and their challenges toward achieving sustainable development goals. J Clean Prod 277:123557

Hardison D, Hallowell M (2019) Construction hazard prevention through design: review of perspectives, evidence, and future objective research agenda. Saf Sci 120:517–526

He M, Lin T, Wu X, Luo J, Peng Y (2020) A systematic literature review of reverse logistics of end-of-life vehicles: bibliometric analysis and research trend. Energies 13(21):5586

Hira M, Yadav S, Morthekai P, Linda A, Kumar S, Sharma A (2018) Mobile phones: an asset or a liability: a study based on characterization and assessment of metals in waste mobile phone components using leaching tests. J Hazard Mater 342:29–40

Hosseini MR, Martek I, Zavadskas EK, Aibinu AA, Arashpour M, Chileshe N (2018) Critical evaluation of off-site construction research: a scientometric analysis. Autom Constr 87:235–247

Ibrahim CKIC, Manu P, Belayutham S, Mahamadu AM, Antwi-Afari MF (2022) Design for safety (DfS) practice in construction engineering and management research: a review of current trends and future directions. J Build Eng 52:104352

Iqbal MW, Kang Y, Jeon HW (2020) Zero waste strategy for green supply chain management with minimization of energy consumption. J Clean Prod 245:118827

Islam MT, Huda N (2018) Reverse logistics and closed-loop supply chain of Waste electrical and electronic equipment (WEEE)/E-waste: a comprehensive literature review. Resour Conserv Recycl 137:48–75

Jäger-Roschko M, Petersen M (2022) Advancing the circular economy through information sharing: a systematic literature review. J Clean Prod 369:133210

Jiang S, Ma J, Liu Z, Guo H (2022) Scientometric analysis of artificial intelligence (AI) for geohazard research. Sensors 22(20):7814

Kannan D, Diabat A, Shankar KM (2014) Analyzing the drivers of end-of-life tire management using interpretive structural modeling (ISM). J Adv Manuf Technol 72(9–12):1603–1614

Katoch R (2022) IoT research in supply chain management and logistics: a bibliometric analysis using Vosviewer software. Mater Today Proc 56:2505–2515

Kaynak R, Koçoğlu İ, Akgün AE (2014) The role of RL in the concept of logistics centers. Proc Social Behav Sci 109:438–442

Kazemi N, Modak NM, Govindan K (2019) A review of reverse logistics and closed loop supply chain management studies published in IJPR: a bibliometric and content analysis. Int J Prod Res 57(15–16):4937–4960

Kianpour K, Jusoh A, Mardani A, Streimikiene D, Cavallaro F, Nor MK, Zavadskas EK (2017) Factors influencing consumers’ intention to return the end of life electronic products through reverse supply chain management for reuse, repair and recycling. Sustainability 9(9):1657

Klöckner CA, Oppedal IO (2011) General vs. domain specific recycling behavior: applying a multilevel comprehensive action determination model to recycling in Norwegian student homes. Resour Conserv Recycl 55(4):463–471

Knickmeyer D (2020) Social factors influencing household waste separation: A literature review on good practices to improve the recycling performance of urban areas. J Clean Prod 245:118605

Kopicki RJ, Berg MJ, Legg L, Dasappa V, Maggioni C (1993) Reuse and recycling: reverse logistics opportunities. Council of Logistics Management, Oak Brook, IL

Kosacka-Olejnik M, Werner-Lewandowska K (2020) Reverse logistics as a trend of XXI century–state of art. Manag Syst Prod Eng. https://doi.org/10.2478/mspe-2020-0002

Koshta N, Patra S, Singh SP (2021) Estimation of E-waste at micro level for reverse logistics: a case of Delhi. J Clean Prod 314:128063

Krippendorff K (2018) Content analysis: an introduction to its methodology. Sage publications

Kwarteng A, Simpson SNY, Agyenim-Boateng C (2021) The effects of circular economy initiative implementation on business performance: the moderating role of organizational culture. Social Responsib J 18:1311

Lee DH, Dong M (2009) Dynamic network design for reverse logistics operations under uncertainty. Transp Res Part e Logist Transp Rev 45(1):61–71

Lee CM, Woo WS, Roh YH (2017) Remanufacturing: trends and issues. Int J Precis Eng Manuf Green Technolgy 4(1):113–125

Li YL, Ying CS, Chin KS, Yang HT, Xu J (2018a) Third-party reverse logistics provider selection approach based on hybrid-information MCDM and cumulative prospect theory. J Clean Prod 195:573–584

Li Y, Kannan D, Garg K, Gupta S, Gandhi K, Jha PC (2018b) Business orientation policy and process analysis evaluation for establishing third party providers of reverse logistics services. J Clean Prod 182:1033–1047

Li C, Feng L, Luo S (2019) Strategic introduction of an online recycling channel in the reverse supply chain with a random demand. J Clean Prod 236:117683

Liao TY (2018) Reverse logistics network design for product recovery and remanufacturing. Appl Math Model 60:145–163

Lima PAB, Delgado FCM, Santos TL, Florentino AP (2022) Medications reverse logistics: a systematic literature review and a method for improving the Brazilian case. Clean Logist Supply Chain 3:100024

Loizides MI, Loizidou XI, Orthodoxou DL, Petsa D (2019) Circular bioeconomy in action: collection and recycling of domestic used cooking oil through a social, reverse logistics system. Recycling 4(2):16

Low MP, Siegel D (2020) A bibliometric analysis of employee-centred corporate social responsibility research in the 2000s. Social Resp J 16(5):691–717

Machado MC, Vivaldini M, de Oliveira OJ (2020) Production and supply-chain as the basis for SMEs’ environmental management development: a systematic literature review. J Clean Prod 273:123141

Mahmoudi M, Parviziomran I (2020) Reusable packaging in supply chains: a review of environmental and economic impacts, logistics system designs, and operations management. Int J Prod Econ 228:107730

Mai ES, Chen H, Anselmi K (2012) The role of returns management orientation, internal collaboration, and information support in reverse logistics. J Transp Manag 23(1):5

Mardani A, Kannan D, Hooker RE, Ozkul S, Alrasheedi M, Tirkolaee EB (2020) Evaluation of green and sustainable supply chain management using structural equation modelling: a systematic review of the state of the art literature and recommendations for future research. J Clean Prod 249:119383

Marginson S (2022) Global science and national comparisons: beyond bibliometrics and scientometrics. Comp Edu 58(2):125–146

Martinez P, Al-Hussein M, Ahmad R (2019) A scientometric analysis and critical review of computer vision applications for construction. Autom Constr 107:102947

Mengist W, Soromessa T, Legese G (2020) Method for conducting systematic literature review and meta-analysis for environmental science research. MethodsX 7:100777

Miafodzyeva S, Brandt N, Andersson M (2013) Recycling behaviour of householders living in multicultural urban area: a case study of Järva, Stockholm, Sweden. Waste Manag Res 31(5):447–457

Mimouni F, Abouabdellah A, Mharzi H (2015) Study of the reverse logistics’ break-even in a direct supply chain. Int Rev Modell Simul 8:277. https://doi.org/10.15866/iremos.v8i2.4901

Mishra S, Singh SP (2020) Designing dynamic reverse logistics network for post-sale service. Ann Oper Res. https://doi.org/10.1007/s10479-020-03710-9

Molano JC, Xing K, Majewski P, Huang B (2022) A holistic reverse logistics planning framework for end-of-life PV panel collection system design. J Environ Manag 317:115331

Mongeon P, Paul-Hus A (2016) The journal coverage of Web of Science and Scopus: a comparative analysis. Scientometrics 106(1):213–228

Moral-Muñoz JA, Herrera-Viedma E, Santisteban-Espejo A, Cobo MJ (2020) Software tools for conducting bibliometric analysis in science: an up-to-date review. Profesional De La Información. https://doi.org/10.3145/epi.2020.ene.03

Neto JQF, Dutordoir M (2020) Mapping the market for remanufacturing: an application of “Big Data” analytics. Int J Prod Econ 230:107807

Nguyen DT, Rameezdeen R, Chileshe N, Coggins J (2021) Effect of customer cooperative behavior on reverse logistics outsourcing performance in the construction industry: a partial least squares structural equation modeling approach. Eng Constr Arch Manag 29:3345